Continuous Electrodeionization CEDI Module

CEDI Modules are the latest technology in Electrodeionization. They simply offer Continuous operation with no need for regeneration of the resin which saves a lot of time and money. Learn more about Continuous Electrodeionization by clicking on this link.

BQUA in conjunction with market experts in the field of CEDI proudly offers a premium line of CEDI modules. With advanced technology and learning the market needs, we give you reasons to choose BQ-ED over other CEDI Modules present in the market:

- Junction box is separated with water nozzles to prevent electric leakage, while other CEDI modules’ junction box is below water inlet. Meaning any water leak may cause electric shock.

- Quick connector, easy to get power supply and avoid the wrong wire connection. In other CEDI Modules you need to open the junction box cover to get power supply.

- Professional hoisting mode, others have special handles.

- Saving installation space, easy to tighten.

- Thicker end plate to improve strength and protect water nozzles.

- Dimension size is lengthened, 316L stainless steel material.

- Standard adapter from English size scale to metric standard,while other companies only make English size scale.

BQ-ED Modules are designed to be installed in either single or multiple Continuous Electrodeionization Module orientations. BQ-ED modules represent compact state-of-the-art design assures ease of installation, maintenance, and service. The CEDI module sizes are designed in optimal flow configurations stated below to ensure cost effectiveness. Table below shows model numbers and nominal flow rates.

| Model | Nominal Flow Rate | Description |

| BQ- ED05-X | 2 gpm [0.44 m3/hr] | CEDI module Single BQ-ED Type – 4 Cell |

| BQ- ED10-X | 5 gpm [1.1 m3/hr] | CEDI module Single BQ-ED Type – 10 Cell |

| BQ- ED20-X | 9 gpm [2.0 m3/hr] | CEDI module Single BQ-ED Type – 18 Cell |

| BQ- ED30-X | 15 gpm [3.3 m3/hr] | CEDI module Single BQ-ED Type – 30 Cell |

| BQ- ED50-X | 22.5 gpm [5.1 m3/hr] | CEDI module Single BQ-ED Type – 45 Cell |

BQ-ED Continuous Electrodeionization CEDI module Side View

Feed Water Requirements CEDI Module – RO Permeate

Feed water for BQ-ED modules must always meet the specifications outlined in Table below:

In most cases, pre-treating BQ-ED modules feed water with reverse osmosis (RO) will bring it within these specifications. Depending on the conditions, however, some sites may require additional pre-treatment. In order to determine if additional pre-treatment is required, below is a feed water requirements reference to compare the BQ-ED feed water (RO Permeate) on site.

| Feed Water Source | RO Permeate |

| Feed Water Conductivity | <40 uS/cm |

| Silica (SiO2) | <1 ppm |

| Iron (as Fe, Mn, S) | <0.01 ppm |

| Maximum Total Chlorine (as Cl) | <0.02 ppm |

| Total Hardness (as CaCO3) | <1.0 ppm |

| Dissolved Organics (TOC as C) | <0.5 ppm |

| pH | 4-11 |

| Temperature | 41-113 F (5-45 C) |

| Inlet Pressure | <100 psi (7 bar) |

Tools and Equipment

- Dolly or fork lift for moving module into place

- Cords, cables or straps to secure to dolly / fork lift

- Wire cutters/strippers

- Adjustable torque wrench with 10-50 ft-lbs. (14-68 N-m) range, 3/8″ (10 mm) drive

- 19 mm extra deep socket

- 19 mm open end wrench

- Screwdrivers (flat blade and Phillips head)

- BQ-ED module handles for moving & positioning unit

Electrical and Plumbing Supplies

The amounts, sizes, and types of these supplies will vary from site to site. Check before hand to determine the site needs:

- Conduit, wires and appropriate conduit connectors to run the DC power and ground from the DC power controller to the module. Size wire in accordance with local electrical code.

- Fittings to connect the 1 1/4″ and 3/4″ BSPM ports on the module to the module plumbing.

What is Continuous Electrodeionization (CEDI)

The continuous electrodeionization is a recent invention that was brought by a water treatment company which patented the CEDI technology. CEDI which is the abbreviation for the continuous electrodeionzation is considered as a smart evolution to conventional Electrodialysis Reversal (EDR) technology. It is introduced as a blend of ion exchange membranes, ion exchange resins and electricity. The difference between the resins used in this technology and the conventional Ion Exchange resins made of divinyl benzene (DVB) is that these resins are continuously regenerated in the continous electrodeionzation without the need for regeneration chemicals or salt.

The way Continuous Electrodeionization CEDI works is so simple. It is actually very similar to Electrocoagulation in respect to the use of plates/electrodes (anode and cathode). Applying a DC current to plates, it turns them to anode and cathode. This is done in order to attract dissolved solids consisted of mainly anions (negatively charges ions) and cations (positively charged ions). The anode electrode will attract negatively charged ions while the cathode will attract positively charged ions. When ion exchange membranes made of cation selective resins are inserted right close to the cathode, it will block the passage of anions and water molecules. On the other hand, when we insert an ion exchange membrane made of anion selective resin close to the anode, it will block the passage of cations and water molecules and only allow anions to pass.

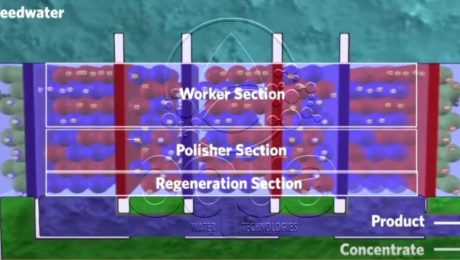

Continuous Electrodeionization Operation and Resin Regeneration

This configuration of membranes and electrodes form the framework of a Continuous Electrodeionization CEDI module. This process is however slowed down by the slow speed of which ions move in water, in fact the low conductivity of water molecules impedes ions removal. Meaning, as ions move outward, the water in the dilute chamber become purified. As ion levels decreases, electrical resistance increases and eventually the whole process slows down. That was solved by adding anions and cations selective resin beads between the two Ion Exchange membranes which reduces the electrical resistance.

The surface of the beads in the continuous electrodeionization CEDI module acts as an ion transport bridge. So that the ions can move quicker through the membranes at to the electrodes. Continuously adding resin beads – Ion Exchange selective membranes sandwiches, creates a series of water purification compartments where product and brine exit the system. As feed water is pumped into the system, it is diverted into separate compartments: concentrate and purification compartments. These two streams remain separated throughout the process because only ions can pass through the membranes. Ions migrate and accumulate in the concentrating compartment where they are washed away into the reject stream; exit the system as concentrate. The water leaving this compartment contain a concentration of ions of approximately 10 – 20x higher than the original feed water. This water can be either drained, recycled or reclaimed for further treatment.

Continuous Electrodeionization CEDI module

At the top of the purification compartment the ion concentration is at its highest. The surface of the resin beads act as a conductive path effectively moving the ions to the membranes. At the lower end of the purification, the ion concentration is reduced to the parts per trillion (ppt) level. The electric field becomes concentrated between the resin beads and the surrounding water resulting an electrochemical reaction. Where water splitting occurring into Hydrogen and Hydroxide ions which is essentially acid and caustic. The acid and caustic generated is what regenerated the resin beads by replacing other trace ions remaining. This exactly what happens in conventional IX deionization systems. A result is a chemical free operation where the electrical potential does all the work and extends the life of the resin.

- Published in Technology, Water Treatment