Ultra-Permeable Membranes (UPM) – Desalination Technology

Recent studies introduce the promise of developing new membrane materials. These materials can desalinate water while showing far greater permeability than traditional reverse osmosis (RO) membranes. But the question remains whether higher permeability means significant reductions in the cost of desalinated water. A research evaluates the potential of ultra-permeable membranes (UPM) to improve the performance and cost of Reverse Osmosis.

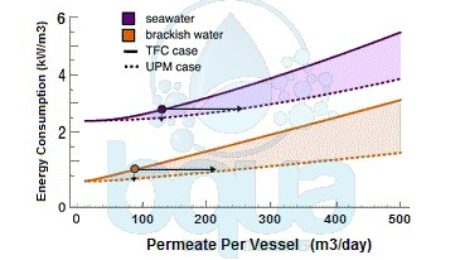

By modeling the mass transport inside a Reverse Osmosis pressure vessel (PV), the study assesses how much tripling water permeability lowers energy consumption. And also lowers the number of required pressure vessels for a particular desalination plant. The findings were very interesting, it proved that a tripling (3x) in permeability permits 44% fewer pressure vessels and 15% less energy for a seawater Reverse Osmosis plant (SWRO). This is done at a both given capacity and recovery ratio. Moreover, tripling permeability results in 63% fewer pressure vessels or 46% less energy for brackish water Reverse Osmosis (BWRO). However, it also shows that the energy savings of Ultra-Permeable Membranes (UPM) exhibits a law of diminishing returns due to thermodynamics and concentration polarization at the membrane surface.

Ultra-Permeable Membranes and Desalination Energy Consumption

The research shows that the development of ultra-permeable membranes helps reducing the energy consumption. It also reduces the number of pressure vessels required for Reverse Osmosis desalination. However, in terms of reducing energy consumption, the benefits of Ultra-Permeable Membranes (UPM) are limited to approximately 15% in the case of SWRO. It also shows that membranes with 3x higher permeability reduces number of pressure vessels by 44% for seawater reverse osmosis RO plants SWRO. And 63% in brackish water RO plants BWRO. This does not affect the energy consumption or permeate recovery.

ultra permeable membranes UPM thin film composite TFC for BWRO and SWRO

In case of energy consumption, ultra-permeable membranes proved to lower energy consumption of Seawater Reverse Osmosis systems – SWRO – by %15. While on the other hand lowered energy consumption of Brackish Water Reverse Osmosis systems – BWRO – by 46%. The research was made at the same permeate flow per pressure vessel as what is typical nowadays.

For greater permeability, the incremental energy savings are negligible but capital requirements continue to decrease. The reason behind it is using fewer pressure vessels. Despite concerns expressed in the research, it shows that concentration polarization does not neglect the benefits of Ultra-Permeable Membranes (UPM). Although it mitigates the benefits relative to what is expected in the absence of concentration polarization. As membrane permeability increases, also typical cross-flow velocities and mass transfer coefficients decrease. Permeate water flux increases routinely with membrane permeability. In spite of the fact that more advanced system designs are required to fully take advantage of greatly increased feed flow rates. Results suggest that advances in membrane science will continue to make desalination highly competitive as a fresh water supply in the near and far future.

- Published in Seawater Desalination

RSS Feed

Reverse Osmosis, Desalination and Water Treatment News RSS Feed Currently Unavailable.

[otw_is sidebar=otw-sidebar-1]

About BQUA

BQUA Company | Reverse Osmosis System

A water treatment company and a market leader. BQUA is among the top leading RO manufacturers of advanced water treatment systems, reverse osmosis systems and desalination plants. We design, build, deliver and commission brackish water reverse osmosis (BWRO) and seawater desalination reverse osmosis (SWRO) utilizing the latest top of the line applied water technologies.

Company’s Mission

As a water treatment company, our mission is to make our customers’ life easier and deliver them solutions that facilitate efforts, exceed specifications, and last beyond the expected life time whenever the Reverse Osmosis system is operated and maintained properly.

Company’s Goal

is to defy water scarcity wherever there is any and resolve the lack of sufficient available water resources to meet the demands of water usage all around the globe.

As a leading water treatment company, we propose the most integrated technology in the reverse osmosis manufacturing industry. All of our reverse osmosis systems are fully equipped with pre-treatment and post-treatment stages, easy to operate, cost effective innovation that meets and exceeds the industry standards.

BQUA understands the tough marine operating circumstances. Our reverse osmosis watermakers are graded and certified to be working in the toughest off-shore and on-shore conditions. Our water treatment systems are reliable, durable and easy to use and maintain.

BQUA strives to design, engineer and manufacture water treatment systems to stand the toughest water treatment conditions and to maintain its leadership and to remain a successful water treatment company.