What is Sedimentation ?

After coagulation occurs followed by a flocculation process before entering a sedimentation basin / clarifier. Flocculated particles enter a sedimentation basin and begin to settle. Particles also referred to as sediments agglomerate to form larger flocs. This process is called sedimentation. When flocs / particles enter a basin and then start to settle, particles’ settling velocities change as particles agglomerate and form larger floc. Because the settling properties of flocculant suspensions cannot be formulated, a clarifier / sedimentation basin performance cannot be accurately predicted. However, for new plants, settling rates can be estimated from batch settling data developed with laboratory jar tests. For expanding existing plants, settling rates can be derived from evaluating the performance of existing basin during various influent water quality conditions. These evaluations often allow for increasing rates for existing basins and establishing higher rates, as compared to published guidelines, for new basins. In an ideal continuous flow basin, sedimentation would take place as it does in the laboratory jar. However, in a real clarifier, wind, temperature density currents, and other factors cause short-circuiting, disruption of flow patterns, breakup of floc, and scouring of the settled sludge. The designer must learn as much as possible about the settling properties of the flocculated solids and then design to match these characteristics. When the designers do not have access to source water data, it is best to select design criteria known to have worked in similar applications, either from personal experience or from regulatory guidelines.

Sedimentation Design Approach

The primary approach in designing conventional sedimentation basins is to select a design overflow rate for maximum expected plant flow. This rate may be chosen based on all units being in service or on one unit being out of service, to allow for redundancy. After selecting a rate, the designer should determine the number of units needed and select the type of sludge collection and removal equipment. The sludge equipment for removing may limit basin dimensions, which could establish the size and num. of units. With the number of basins selected, the designer should proceed to design inlet and outlet conditions and finalize dimensions to suit all design parameters and site conditions. The following are suggested guidelines for the various design parameters.

Sedimentation Overflow Rates

Hydraulic overflow rate is the primary design parameter for sizing sedimentation basins. This rate is defined as the rate of inflow Q divided by the tank surface area A. Units are typically rated in gallons per day per square foot, gallons per minute per square foot, or cubic meters per hour per square meter. Acceptable rates vary with the nature of the settling solids, water temperature, and hydraulic characteristics of the settling basin.

After evaluation of both cold & warm water loading rates, the design rate is based on whichever is more critical. Plant flow variations between warm and cold water periods often allow selection of higher rates for summer operation than the typical suggested loading rates. Overflow rates can also be selected based on pilot studies. Piloting of conventional settling basins is not especially reliable, but it is often done using tube settlers. Data from such studies, along with jar testing, are often useful in design. Pilot testing of other types of settling, especially proprietary processes, is useful and is recommended.

Detention Time

Which is the flow rate divided by tank volume, is usually not an important design parameter. Many regulatory agencies (e.g., Great Lakes, 2003), however, still have a requirement for detention periods of 4 h. It is likely that this detention requirement is a carryover from the days of manually cleaned basins designed to provide the sludge storage zone. These basins were often 15 to 16 ft (4.6 to 4.9 m) deep or greater and operated so that more than one-half the volume could be filled with sludge before being cleaned. Real time could vary from 4 h when clean to less than 2 h just before cleaning. Modern designs with mechanical sludge removal equipment need not provide a sludge zone, and deep basins with long detention times are no longer required. Conventional basins with detention times of 1.5 to 2.0 h provide excellent treatment.

Basin Depth and Velocities

In theory, basin depth should not be an important parameter either, because settling is based on overflow rates. However, in practice, it is important because it affects flow-through velocity. Flow-through velocities must be low enough to minimize scouring of settled floc blanket. Velocities of 2 to 4 ft/min (0.6 to 1.2 rn/min) usually are acceptable for basin depths of 7 to 14 ft (2.1 to 4.3 m), the hallower depths often used with multiple-tray basins. Single-pass basins are generally deeper, to offset the effects of short-circuiting from density and wind currents.

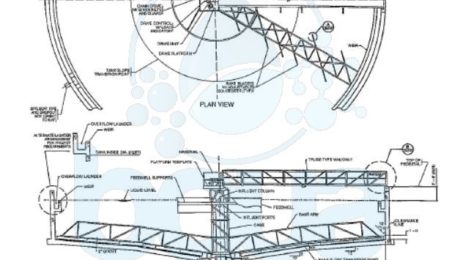

Circular Sedimentation Basin / Clarifier design

- Published in Technology