What is Diatomaceous Earth DE Filter

Diatomaceous Earth DE filtration – DE Filter –  has been used effectively for drinking water treatment since 1942. Diatomaceous Earth DE Filter was adopted as a standard method for the U.S. Army. The DE filter was selected because of its portability and effectiveness in removing Entamoeba histolytica cysts (Black and Spaulding, 1944). These cysts are pervasive in some parts of the world and are difficult to control with disinfectants alone. The capability of DE filter to effectively remove particulates applies equally well to the latter concerns of Cryptosporidium and Giardia. Where cyst removals of approximately 6 logs have been achieved (Ongerth and Hutton, 1997). DE filter is commonly called a pre-coat filter because of the pre-coat of filter leaves that initiates every operating cycle.

Although DE filter has DE as the most common pre-coat material used, other pre-coat material such as ground perlite performs as well in many applications. For many years, the type of equipment available limited the use of a Diatomaceous Earth DE filter for municipal drinking water treatment. The use of stainless steel and plastics in the fabrication of equipment has significantly changed the performance capability of the filters by improving their ease of operations and maintenance. DE Filter named upon Diatomceous Earth which is mined from the fossilized remains of microscopic plants called diatoms, deposited in what were the beds of ancient oceans. A powdered medium is manufactured from the diatomite deposits that is almost pure silica. One of the more common diatomite media used for drinking water treatment has a mean particle size of 22.3/xm with 80% of the particles ranging in size from 5 to 64 p~m. This medium, when deposited on the filter septum, has an average pore size of about 7.0/xm.

Diatomaceous Earth Filter Operation

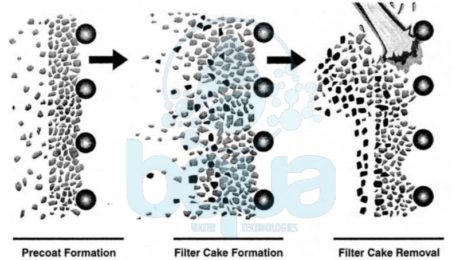

As illustrated below, Diatomaceous Earth DE filter operations occur in three steps:

1. A precoat of about % in. (3 mm) is deposited on the filter.

2. After the precoat has been deposited, filtering begins. And at the same time a small amount of Diatomaceous Eearth material (called body feed) is added to the source water. This is to maintain the porosity of the media.

3. Particulates in the source water are trapped in the pre-coat layer until it reaches maximum head loss. At which time the filter run is terminated and media material is cleaned from the septa.

diatomaceous earth DE filter operation design

Porosity Control of DE Filter

The principal requirement for maintaining effective Diatomaceous Earth DE filter runs is to maintain the porosity of the filter cake. Source water solids generally vary in size and are mixture of relatively inert matter and solids that are predominantly organic. If source water is filtered through the pre-coat alone, the buildup of solids and compression of the accumulated cake quickly reduces DE filter cake porosity. And head loss increases at an exponential rate. This may be avoided by adding body feed to the source water in sufficient amounts to produce a constant flow versus head loss relationship. Although the rate of flow does not affect effluent quality or turbidity breakthrough, the flow rate for pre-coat filters should generally be limited to about 2 gpm/ft 2 (7.8 m/h). The shape of the pre-coat filter head loss curve that reflects both feed and flow conditions is. Therefore, an important feature to control effective filter run performance.

Supplementary Treatment for Diatomaceous Earth DE Filter

Supplementary measures are added to the basic DE filter process to enhance the filtration process and to expand the process to remove some non-particulate constituents. Natural color in source water supplies is caused by either organic or mineral matter. Color results from the decay of plant matter or from the solubilization of iron in the soil. And in many instances the mineral and organic matter are bound together. Therefore color is present either in particulate form or in solution. Particulate color consists mostly of negatively charged colloids, and even though the pre-coat medium has low pore size, charged colloids pass through unless the charge is neutralized.

The use of a strong oxidant such as ozone has been demonstrated to be effective in conditioning color for removal. When color is particulate rather than dissolved, DE filters reduce source water color of about 25 color units (CU) and less to below 5.0 CU. With source color between 25 and 60 CU, filter effluent is generally no higher than 10 CU. Supplemental treatment such as pre-ozonation or alum-coated media may be required. They can improve removal of particulate color and to reduce dissolved color. Dissolved iron precipitates by aeration or by adding a strong oxidant so that the iron is removed as a particulate in DE filtration. The use of magnesite (magnesium oxide) is found to facilitate removal of some forms of iron. Magnesite mixed along with body feed is held for about 10 rain to form negatively charged suspension of magnesium oxide. MgO gradually undergoes hydration and solution.

Manganese may be removed with DE filer with potassium permanganate (KMnO4) added to the body feed. Followed by flow detention, usually from 10 to 20 min. Detention time is important and should be determined in bench and pilot tests. The rate of KMnO4 addition and body feed rate depend on the amount of manganese in the source water. And on also other water quality characteristics. Where iron and manganese are both present in source water, supplementary conditioning must usually be accomplished in separate steps. With iron treatment preceding the KMnO4 addition. When there is a large amount of iron to be removed, it may be necessary to have two filters in series. With iron conditioning preceding the first filter and the addition of KMnO4 and detention between the first and second filters.

Practically the only carryover of solids in DE filter effluents would be very fine Diatomaceous Eearth particles used in pre-coat and body feed. Although the presence of these particles is innocuous to health, effluent water turbidity must meet the established requirements. Use of a finer Diatomaceous Eearth for pre-coat can sometimes achieve lower turbidity levels. A slight reduction in the applied flow rate can also help to improve effluent turbidity. Where only slight additional turbidity reduction is needed. The use of a simple cartridge filter following the DE filter accomplishes the desired DE removal. Use of cartridge filters to polish the effluent will be more effective for the lower-capacity DE installations when solids carryover is minimal. Note that without the addition of separate, additional treatment processes, DE filtration will not reduce the organic content of source water.

You can learn more about the Diatomaceous Earth DE Filter Design

Reference: Water Treatment Plant Design

- Published in Technology, Water Treatment