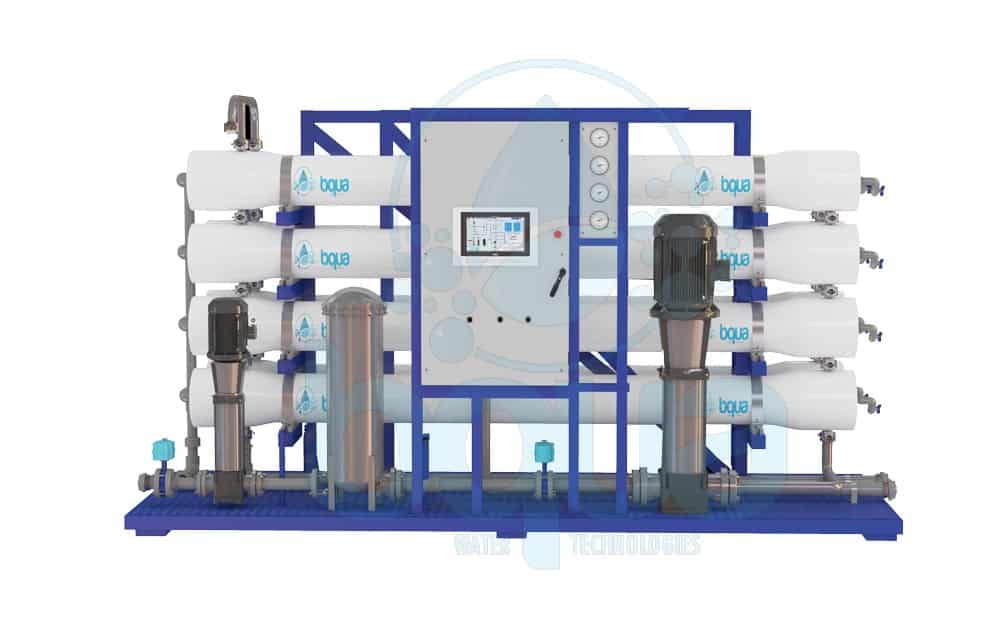

BQUA's Industrial BQIX-BW Reverse Osmosis System is integrated and manufactured to exceed expectations and solve your toughest water problems. Our future-proof series is well known for its durable construction, user friendly operating system, environmental friendly materials, plug and play turnkey operation and hassle-free operation.

All BQUA RO Systems series including the BQIX-BW are customizable based on each individual water contaminants and design. Additional equipment can be added if necessary based on each case, include water softener, media filter, chemical dosing, iron removal filter, CIP cleaning skids, anti-scalant, etc. The BQIX-BW series has capacities ranging from 200,000 GPD to 900,000 GPD. With feed water TDS ranging from 1000 ppm to 10,000 ppm. These features have the capability of removing all organic and inorganic contaminants; hardness, arsenic, chlorine, odor, taste, smell, color, iron, sulfur, fluoride and a lot more. BQUA industrial brackish water reverse osmosis system represents the premium top of the line technologies in the water treatment industry and is capable of removing dissolved salts, particles, minerals, solids and other contaminants from water with a molecular weight greater than 150-250 Dalton. We partner with major market players in the field of water treatment and only use top quality brands and the most reputable manufacturers; Pentair, Dow, Hydrodex and Siemens.

Industrial Brackish Water Reverse Osmosis Product Specifications

Operation Specifications

|

-

Maximum feed water temperature: 42°C

-

Hydrogen Sulfide must be removed

-

Maximum Silica tolerance: 25 ppm at 60% recovery

|

-

Feed water TDS: 0-2,000 ppm

-

Operating pressure: 150 to 250 psi

-

pH tolerance range: 3-11

-

Max. Iron content: 0.05 ppm

|

-

Feed water pressure: 20 to 80 psi

-

Hardness over 1 GPG requires water softener

-

Turbidity should be removed

-

Operate at higher TDS by lowering recovery

|

|

BQUA BQIX-BW Series Product Specifications by model number

| Industrial Brackish Reverse Osmosis System BQIX-BW Series |

| Model Number |

Permeate Flow Rate |

Membranes |

Motor Rating at 1,000 ppm |

| GPD |

M3/Day |

Size |

Qty. |

60Hz (hp) |

50Hz (kw) |

| BQ200K-BW |

200,000 |

758 |

8" X 40" |

28 |

30 |

22 |

| BQ225K-BW |

225,000 |

852 |

8" X 40" |

30 |

30 |

22 |

| BQ270K-BW |

270,000 |

1,023 |

8" X 40" |

36 |

40 |

30 |

| BQ320K-BW |

320,000 |

1,212 |

8" X 40" |

42 |

40 |

30 |

| BQ360K-BW |

360,000 |

1,364 |

8" X 40" |

48 |

50 |

37 |

| BQ410K-BW |

410,000 |

1,553 |

8" X 40" |

54 |

60 |

37 |

| BQ450K-BW |

450,000 |

1,705 |

8" X 40" |

60 |

60 |

45 |

| BQ500K-BW |

500,000 |

1,894 |

8" X 40" |

66 |

60 |

45 |

| BQ550K-BW |

550,000 |

2,083 |

8" X 40" |

77 |

75 |

45 |

| BQ600K-BW |

600,000 |

2,273 |

8" X 40" |

91 |

100 |

55 |

| BQ700K-BW |

700,000 |

2,652 |

8" X 40" |

98 |

100 |

75 |

| BQ800K-BW |

800,000 |

3,030 |

8" X 40" |

112 |

2 X 60 |

2 X 37 |

| BQ900K-BW |

900,000 |

3,409 |

8" X 40" |

126 |

2 X 60 |

2 X 37 |

| For more information, please feel free to ask a BQUA specialist |

Standard and Available Features:

| Standard Features: |

Available Options: |

- NEMA 4x enclosure.

- Pressure switch.

- Liquid filled pressure gauges.

- Permeate conductivity monitor.

- Permeate & concentrate flow meters.

- Powder coated stainless steel or carbon steel frame.

- 8” Thin Film Composite spiral wound membrane.

- Stainless steel multi-stage pump.

- FRP membrane housing.

- 5 micron cartridge pre-filter.

- Media Filter.

- 380-415V/3Ph/50Hz power supply.

- Microprocessor based control panel. Conventional

control panel also available.

- Programmable time delay and set points.

- Status indicators.

- Motor starter.

- Chemical dosing systems.

|

- Concentrate Recycle.

- 460V/3Ph/60Hz power supply.

- Export crate.

- 220V/Single phase/50Hz power supply.

- Iron removal filter.

- Ozone / UV sterilization systems.

- Water softener.

- De-ionization post filter.

- Product tank level controller switch.

- Feed pH monitor with sensor.

- Feed water conductivity monitor.

- Membrane cleaning skid.

- Automatic hourly flush.

- ORP monitor with sensor.

- Water and hour meters.

|